About us

Who we are

Our products serve as an integral part of almost every product for people,

from food packages to industrial packages to Special purpose applications.

(Fresh food, Frozen food, Heated food / Cosmetics, Household goods, toys / Medical container packages, Cooling/Freezing showcase parts)

Sustainability for humanity, This is the future of the pet sheet industry that JINYOUNG Chemical believes.

Our products serve as an integral part of almost every product for people, from food packages to industrial packages to Special purpose applications. (Fresh food, Frozen food, Heated food / Cosmetics, Household goods, toys / Medical container packages, Cooling/Freezing showcase parts) Sustainability for humanity, This is the future of the pet sheet industry that JINYOUNG Chemical believes.

About us

History

We believe that the most eco-friendly products are good for people,

that good people make good products, and that our belief realizes the products we make.

-

Company Establishment & PET Sheet Production

-

2000. 06

Established Jinyoung Chemical Co., Ltd.

Engineering Plastics

-

2009. 11

Constructed New Headquarters and Installed 1st Extruder

Production Capacity: 400 tons/month

-

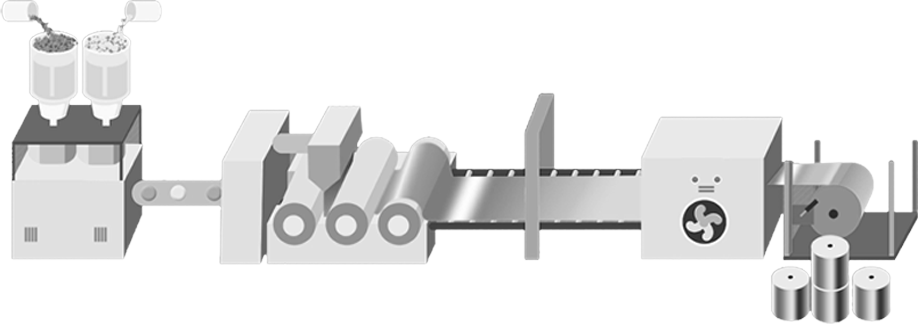

Multi-layer Extrusion Equipment

-

2010. 08

Installed 2nd Extruder

Production 550 tons/month

Total CAPA 950 tons/month -

2011. 06

Acquired ISO 9001 Certification

-

2011. 10

Established Jinyoung Co., Ltd.

Transferred Engineering Distribution Business

-

2012. 11

Installed 3rd Extruder

Production 450 tons/month

Total CAPA 1,400 tons/month -

Production Capability: 0.15–2.0mm Thick PET Sheets

-

2014. 05

Established Corporate R&D Center

-

2014. 10

Relocated and Expanded Main Factory

-

2014. 12

Installed 4th Extruder

Production 700 tons/month

Total CAPA 2,100 tons/month -

Expansion into the U.S. Market

-

2016. 05

Established U.S. Sales Corporation

Located in Fullerton, CA

-

2016. 12

Installed 5th Extruder

Production 600 tons/month

Total CAPA 2,700 tons/month -

2019. 01

Constructed 2nd Factory

Installed PP Extruder and PET 6th Line

Production 1,000 tons/month

Total CAPA 3,700 tons/month -

2020. 04

Installed 7th Extruder

Production 600 tons/month

Total CAPA 4,300 tons/month -

2020. 08

Established U.S. Manufacturing Corporation

Mound House, Carson City, NV

Installed PET Extruders No.1 & No.2

1,000 tons/month

-

2024. 03

Installed Extruders No.8 & No.9

Production 700 tons/month

Total CAPA 5,000 tons/month

CONTACT US

Jinyoung chemical Co.,Ltd.

- Company Name

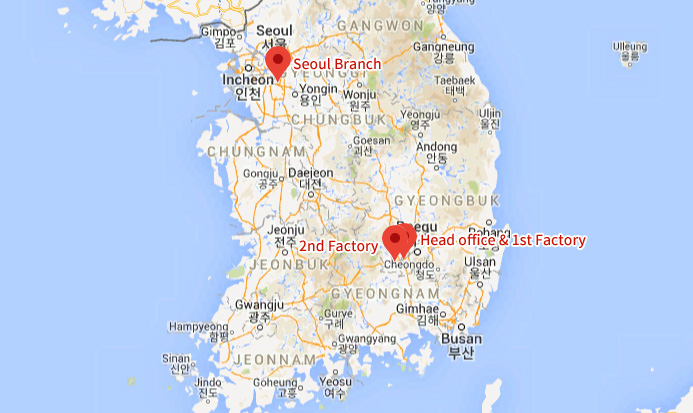

- Jinyoung chemical Head office & 1st Factory

- Address

- 236, Dasansandan-ro, Dasan-myeon, Goryeong-gun, Gyeongsangbuk-do, Korea. 40113

- Tel

- +82-53-593-7102

- Fax

- +82-53-593-7103

- sales@jychemical.com

- Factory

- Jinyoung Chemical 2nd Factory

- Address

- 78, Donggoryeongsandan-ro, Seongsan-myeon, Goryeong-gun, Gyeongsangbuk-do, Korea 40115

- Tel

- +82-53-593-7100

- Fax

- +82-70-8240-5555

- Company Name

- Jinyoung chemical Seoul Branch

- Address

- B-#1303, Pyeungchon Hifield, 66, Beolmal-ro Dongan-gu, Anyang-si, Gyeonggi-do, Korea, 14058

- Tel

- +82-31-689-3636

- Fax

- +82-31-689-3637

- sales@jychemical.com

JYC America Inc

- Company Name

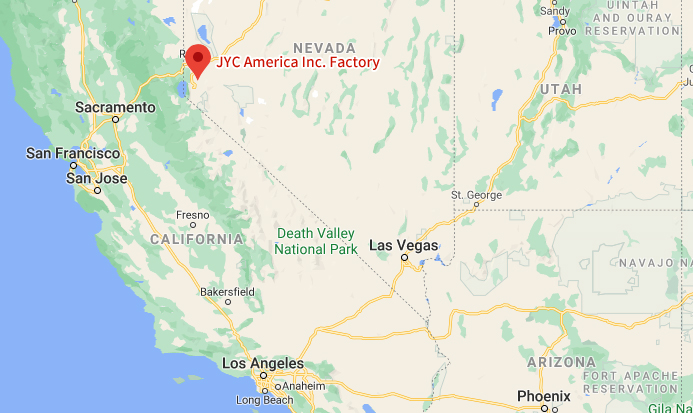

- JYC America Inc. Factory

- Address

- 16, Bruce way, Mound House, NV, 89706, USA

- Tel

- +1 775 257 7010

- sales@jychemical.com